It takes a lot of moving parts to produce a single shoe—seven to be exact—in our case. And, unfortunately, when one of these “parts” is missing, the entire production of the product is put on hold. COVID-19 continues to trickle into brands’ supply chains and devastatingly, it’s often its most vulnerable members that are affected the worst. When brands cancel orders or withhold payments from their factories and suppliers, it reveals “an imbalance of power between big brands and developing economies”. Research from Traidcraft Exchange shows that the economic circumstances of most producing countries render them unable to support large populations of unemployed workers, and lack the healthcare infrastructure to care for the infected.

At Poppy Barley, we pride ourselves on running a transparent supply chain that supports our entire team, from those working in our factories in Mexico to our head office and retail staff in Alberta. Earlier last week, our co-founder, Justine, interviewed Lupita, one of our long-time factory owners, sharing the reality of COVID-19’s impact on artisans, Mexico, and business as a whole.

Justine: Can you share a little bit about yourself?

Lupita: My name is Guadalupe. In Mexico, everyone with the name Guadalupe is nicknamed Lupita, so that’s what I go by. I’m 49 years old, married and have 3 children ages 23, 21 and 19, all of whom are in university. My oldest is studying to be an architect, my daughter a doctor and my youngest an engineer.

Justine: How long have you owned a footwear factory? How did you get started?

Lupita: I’ve owned a footwear factory for 17 years—I started it at 32! After completing my business degree, I worked in the export department for a larger footwear company. I started working as a consultant for an American businessman trying to make high-quality custom shoes for men in low volume. After two years of looking and vetting other factories—and being disappointed—we decided to start our own company as partners in 2013. I started with 3 shoemakers and myself.

Justine: We met Lupita in 2012 after the 12-year-old daughter of our shoe broker connected us through Lupita’s daughter, Alba, who’s now in med school! It’s crazy. At the time, she’d converted a small old house into a boutique factory and had about 10 shoemakers.

Since then she’s moved into a larger space twice. The last time she moved was right before COVID-19 blew up—we got to show the shoemakers the new, improved space together for the first time in early February 2020 when I was there on a trip to Mexico. The new space has been a blessing and a curse. They have a lot of space to social distance but also higher overhead expenses now in tough times.

Justine: When did COVID-19 escalate in Mexico? What happened and what was it like?

Lupita: We had our first COVID-19 case in late February and things escalated until mid-March. That was when our government declared a state of emergency. Schools were closed in late February and most businesses shut down mid to late March. We were able to keep working for a few weeks longer by having our elderly workers stay home, picking up the shoemakers who would normally take public transit and moving apart all our machines and work stations so that everyone could social distance. We also started to work in shifts so we could have smaller groups.

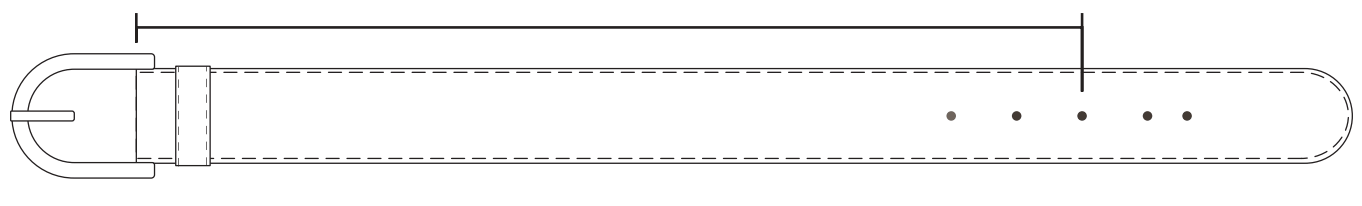

Justine: At this point the factories are all closed and are supposed to open in June. Something that worries me for reopening is that footwear has a very complicated supply chain—each shoe has about 7 components, and those components have sub-components made from other suppliers—so one small gap in it means you can’t make a shoe. That would put us, Lupita and Poppy Barley, in a tough position. We both have no business without product to make and sell. So hopefully everything re-opens in tandem, and most importantly, safely.

Justine: As a business owner during COVID-19 what have been your challenges?

Lupita: Our main concern was the risk of having to terminate our team because more than 30 families depend on our operations.

Justine: Unlike in Canada, where the government came out with the wage subsidy program, deferred tax and other payments for businesses and provided new forms of credit, in Mexico the government has not helped businesses survive. They’ve said businesses have to figure this out on their own. This has made an incredibly challenging situation for business worldwide, and much harder for our Mexico partners.

Globally, the fashion supply chain is incredibly stressed. Most brands are facing plunging demand and, in turn, cancelling orders from factories in countries with a weaker social service net than Canada. In the past couple of weeks we’ve worked with Lupita to create a minimum value of monthly orders for the rest of 2020 to ensure her business survives.

Justine: How optimistic or pessimistic do you feel for the rest of 2020? What worries you, and what might excite you?

Lupita: I feel optimistic about the rest of 2020, even though we’re aware the recovery will be slow. This has been a lesson for everybody to reinvent the wheel, not only at home but also at work. I’m confident we’ll be able to keep going because our team is very responsible for maintaining their health and optimism! And, we know we count on our customer’s support as well. We might have to make some additional shoes but we have a very open-minded team that’s willing to learn and do whatever is necessary to survive.

Justine: And that’s why Lupita is such a great partner for us and has been for many years. She’s relentlessly optimistic and inventive.

To learn more about our factories and supply chain, read here. If you want to learn more about how COVID-19 has affected global supply chains, visit Fashion Revolution.